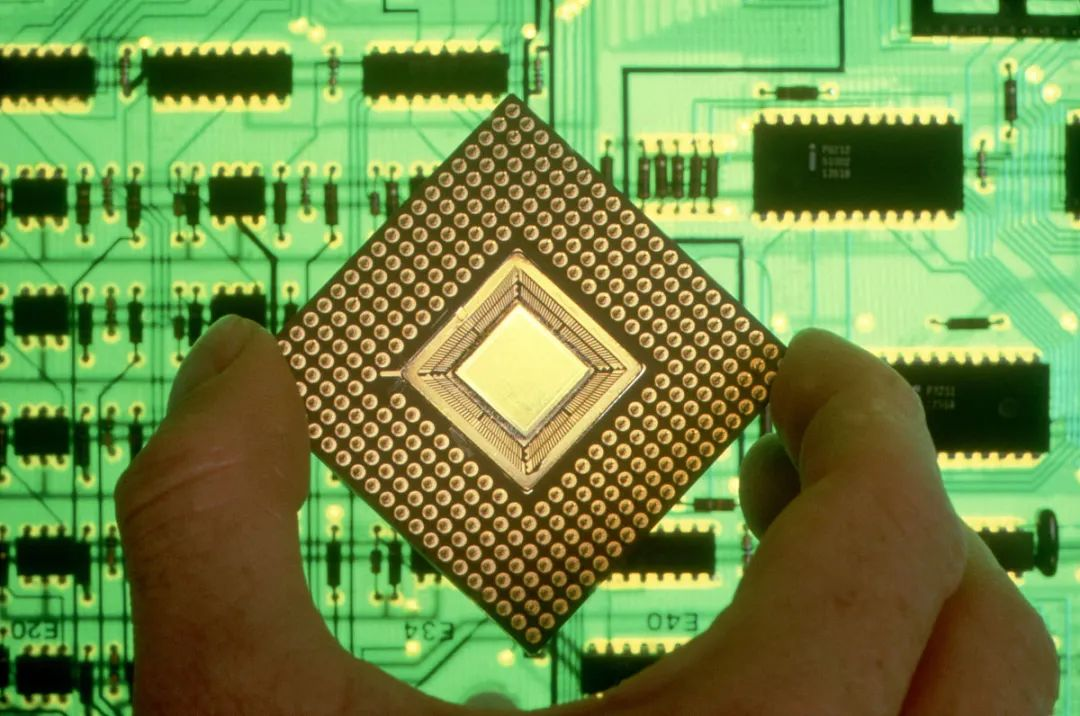

In the field of modern micro -electronics manufacturing, the surface character recognition of chip is a vital process. It is related to multiple key links such as product information traceability, anti -counterfeiting verification and quality control. With the advancement of science and technology, especially the development of machine vision and deep learning technology, this problem that originally relied on artificial or traditional optical recognition methods has been efficient and accurate.

Machine vision technology captures small character images on the surface of the chip through precise industrial cameras, and combines advanced image processing algorithms to analyze the collected data in real time. However, the surface characters on the chip are often tiny and tightly arranged, putting forward extremely high requirements for the resolution, stability and anti -interference ability of the identification system. At this point, the virtual Digital Technology proposes the high -precision application of deep learning algorithms in the visual of the machine. In this context, the DLIA industrial defect detection plays a decisive role.

The DLIA industrial defect detection By constructing a deep neural network model, the system can automatically learn and extract features from massive training samples, thereby achieving precise identification of complex and fine characters on the chip surface. Even in the face of image quality fluctuations caused by light change, angle deviation, or surface reflection, deep learning algorithms can be quickly adapted and made accurate judgments.

With the deep fusion of machine vision and deep learning, the degree of automation and accuracy of chip surface character recognition has been greatly improved, significantly improved production efficiency, reducing human error risk, and providing details for subsequent product quality management and process optimization of process optimization. Reliable data support.

This deep learning -enabled machine visual technology breaks through the limitations of traditional character recognition in accuracy and speed. Even the most subtle scratches, pollution or deformation can be discovered and recorded in time, which greatly improves the level of surface quality control level It effectively reduces the rate and repairs in the production process.

The surface character recognition of the chip, as an important application scenario of machine vision technology in the microelectronics manufacturing industry. With its excellent performance of fusion and deep learning, it has become one of the key driving drivers for the high -quality development of the industry. New era of industrial quality inspection.

For more electronic conponents,please refer to:https://www.ciselec.com/en/products.html